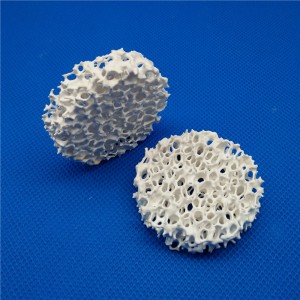

Alumina Ceramic Foam Sefa yeMolten aluminium alloy filtration

Alumina Ceramic Foam Sefa yeMolten aluminium alloy filtration

| Dimension (mm) | Dimension (inch) | Kudurura (kg/s) | Kusefa simba (tani) |

| 178*178*50 | 7*7*2 | 0.2-0.6 | 5 |

| 228*228*50 | 9*9*2 | 0.3-1.0 | 10 |

| 305*305*50 | 12*12*2 | 0.8-2.5 | 15 |

| 381*381*50 | 15*15*2 | 2.2-4.5 | 25 |

| 430*430*50 | 17*17*2 | 3.0-5.5 | 35 |

| 508*508*50 | 20*20*2 | 4.0-6.5 | 45 |

| 585*585*50 | 23*23*2 | 5.0-8.6 | 60 |

| Material | Alumina |

| Color | Chena |

| Pore Density | 8-60ppi |

| Porosity | 80-90% |

| Refractoriness | ≤1200ºC |

| Bending Strength | >0.6Mpa |

| Kusimbisa Simba | >0.8Mpa |

| Volume-uremu | 0.3-0.45g/cm3 |

| Thermal shock resistance | 6 nguva / 1100ºC |

| Application | Aluminium, Aluminium alloys uye mamwe maAruminiyamu asina-ferrous alloys |

1. Bvisa tsvina yesimbi yakanyunguduka

2. Yakareruka gating system

3. Kuvandudza metallurgical structure ye castings

4. Kuderedza kusakanganiswa kwezvikasa

5. Kuvandudza chiyero chekukanda

6. Deredza kukanda mukati re-oxidation defects

7. Deredza kukanganisa kwepamusoro mushure mekugadzira machina ekukanda

1.Kuwedzera Fluidity

Kubvisa inclusions kunoita kuti simbi iwedzere kuyerera, zvichiita kuti zvive nyore kuzadza mold, zvirinani kukanda chimiro, uye nani mutete chikamu castability.

2.Reduced Mold uye Die Wear

Kubvisa inclusions uye mamwe marara asiri emetallic kubva mukunyunguduka kunoderedza kufa soldering uye mold-metal kupindirana, izvo zvinosvibisa mold pamusoro uye hupenyu hwebasa.

3.Longer Tool Life

Oxide pamwe neiyo intermetallic inclusions inogadzira "nzvimbo dzakaoma" dzinokuvadza maturusi mukugadzira uye kupedza mashandiro.Kusefa kunoderedza kupfeka kwezvishandiso uye kunowedzera kugadzirwa.

4.Vashoma Vanoramba

Inclusions nucleate porosity, inogadzira misodzi inopisa panguva yekusimba, inokonzeresa kuremara kwepamusoro kunoshatisa chitarisiko, uye kazhinji kunoderedza michina zvinhu.Muzviitiko zvakawanda, kuchekwa kwesefa kunoramba kubva kune zvikonzero zvakadaro kusvika kune zero.Kuvandudzwa kwegoho kusvika pedyo ne100% uye kuderedzwa kwemitengo yekuramba kusvika pa kana pedyo ne0% zvakajairika.

1. Kukanda jecha

2. Kukanda makungu

3. Low-pressure die casting

4. Permanent mold kukanda

5. Kubata uye kutamisa masisitimu